5.HX

Hydrocarbon

Extractor

5.HX

Hydrocarbon

Extractor

CRAFT SCALE

PERFECTLYCRAFTED EXTRACTS

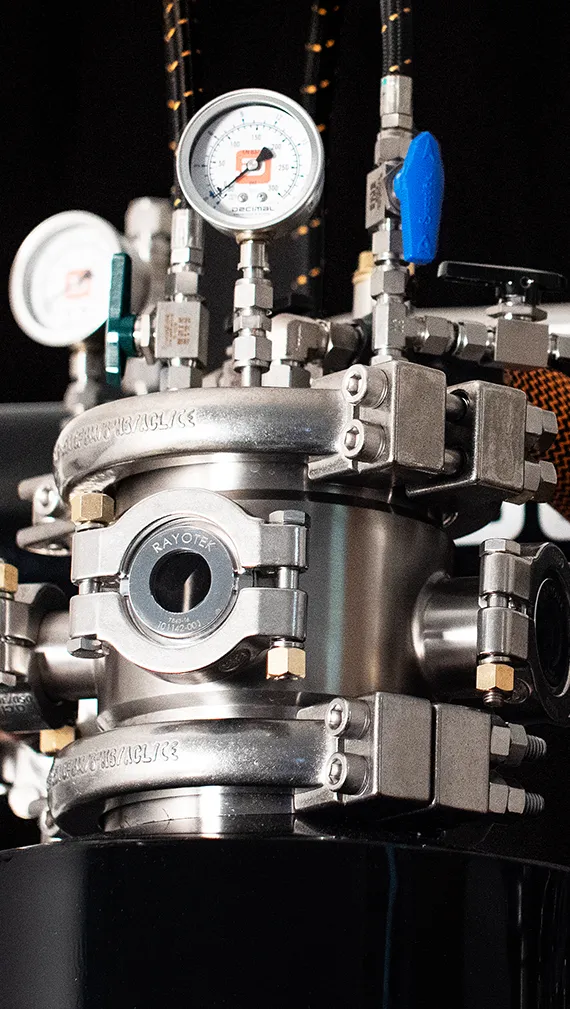

5.HX is a hydrocarbon extractor designed for quality. Precise temperature control and C1D1 tablet interface provide an unparalleled command for extraction of 5 lbs. per run – 10 lbs. per hour.

Passive recovery with a horizontal tube in shell condenser and integrated load sensors eliminate the need for noisy compressor pumps and expensive C1D1 scales. The fully jacketed system includes inline CRC filtration and molecular sieves for fresh frozen processing — everything you need for award-winning BHO!

Extraction

Made Easy

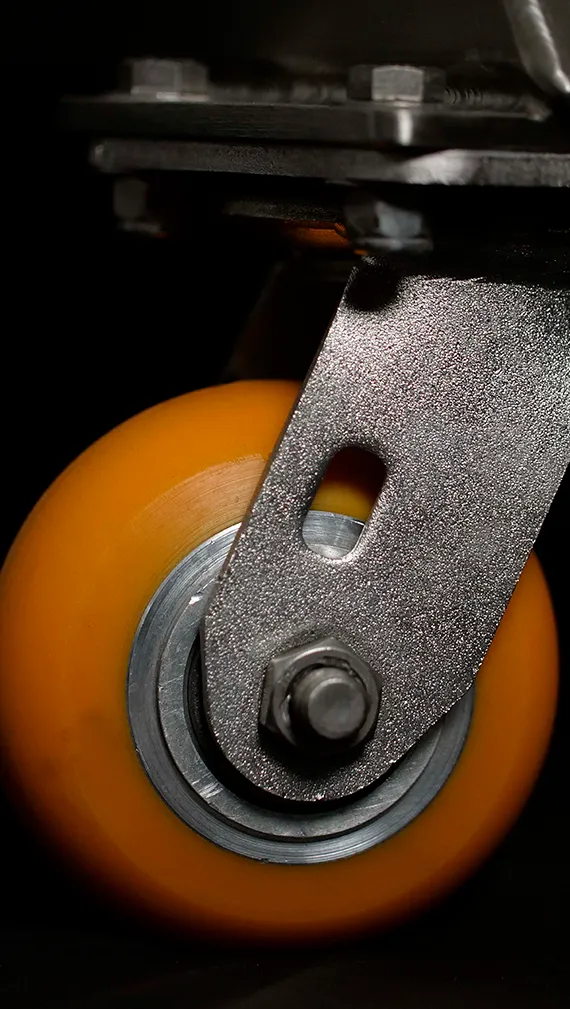

5.HX is designed for safe, single-user operation, with advanced features for simple operation. Color-coded valve handles make SOPs easy to follow, and an integrated mesh workbench allows ergonomic vessel loading and unloading. The C1D1 touchscreen interface allows chiller operation from inside the extraction booth. Everything you need, at your fingertips.

Partners

For Life

All Decimal machines are proudly designed and manufactured from the ground up in Canby, Oregon. Decimal uses the best materials and backs its stainless steel with a Lifetime Warranty. Quality you can build your business upon, with a support team to back you up — that’s our promise.

Partners

For Life

All Decimal machines are proudly designed and manufactured from the ground up in Canby, Oregon. Decimal uses the best materials and backs its stainless steel with a Lifetime Warranty. Quality you can build your business upon, with a support team to back you up — that’s our promise.

Partners

For Life

All Decimal machines are proudly designed and manufactured from the ground up in Canby, Oregon. Decimal uses the best materials and backs its stainless steel with a Lifetime Warranty. Quality you can build your business upon, with a support team to back you up — that’s our promise.

ADVANCED

AUTOMATION

5.HX is loaded with cutting-edge technology, from internal temperature probes that measure extraction temperature to internal load cells that record solvent usage, all operational parameters are displayed and controlled inside the extraction booth.

Advanced

Automation

5.HX is loaded with cutting-edge technology, from internal temperature probes that measure extraction temperature to internal load cells that record solvent usage, all operational parameters are displayed and controlled inside the extraction booth.

Advanced

Automation

5.HX is loaded with cutting-edge technology, from internal temperature probes that measure extraction temperature to internal load cells that record solvent usage, all operational parameters are displayed and controlled inside the extraction booth.

SPECIFICATIONS

EQUIPMENT | |

|---|---|

Dimensions (approx.) | 75”L x 31”W x 74”H |

Working Area: | 17 sq. ft.² |

Vacuum | Welch CRVPro 4 Explosion Proof |

Warranty** | Lifetime Warranty against pitting or corrosion. |

TECHNICAL | |

|---|---|

Solvents | Butane, Propane, Isobutane |

Solvent to Biomass | 5:1 |

Recovery Method | Passive |

Cycle Time | Approx. 30 minutes (Note: Runtimes vary according to factors such as solvent blend, operating temps, solvent to material ratio, other factors) |

Capacity | Approx. 80 lbs. per 8 hour shift |

Solvent Recovery Rate | 1 lbs. per minute |

Peer Reviewed | Pressure Safety Inspectors |

Certifications | Meets or exceeds all industry listed standards for: ASME Section VIII, GMP, IFC 3904.4, NFPA 1: 38.6.1.5.6.1, 3-A Sanitary Standard, Class 1 Division 1, NSF and UL21. C1D1 |

TECHNICAL | |

|---|---|

Solvents | Butane, Propane, Isobutane |

Solvent to Biomass | 5:1 |

Recovery Method | Passive |

Cycle Time | Approx. 30 minutes (Note: Runtimes vary according to factors such as solvent blend, operating temps, solvent to material ratio, other factors) |

Capacity | Approx. 80 lbs. per 8 hour shift |

Solvent Recovery Rate | 1 lbs. per minute |

Peer Reviewed | Pressure Safety Inspectors |

Certifications | Meets or exceeds all industry listed standards for: ASME Section VIII, GMP, IFC 3904.4, NFPA 1: 38.6.1.5.6.1, 3-A Sanitary Standard, Class 1 Division 1, NSF and UL21. C1D1 |

Highlights

- Touchscreen HMI allows control of chillers and vac from inside the extraction booth

- Digital gauge displays actual temperature inside solvent tank

- Integrated load sensors track solvent usage, replacing C1D1 scale

- Designed for extraction down to -60°C

- Color-coded valve handles and labeled valve plates make SOPs easy to follow

- Removable mesh work bench conveniently hold vessel lids and tools for easy access

- PSI peer-reviewed, 50 state compliant, ASME certified, UL

- On-site training and installation service

Highlights

- Touchscreen HMI allows control of chillers and vac from inside the extraction booth

- Digital gauge displays actual temperature inside solvent tank

- Integrated load sensors track solvent usage, replacing C1D1 scale

- Designed for extraction down to -60°C

- Color-coded valve handles and labeled valve plates make SOPs easy to follow

- Removable mesh work bench conveniently hold vessel lids and tools for easy access

- PSI peer-reviewed, 50 state compliant, ASME certified, UL

- On-site training and installation service

Highlights

- Touchscreen HMI allows control of chillers and vac from inside the extraction booth

- Digital gauge displays actual temperature inside solvent tank

- Integrated load sensors track solvent usage, replacing C1D1 scale

- Designed for extraction down to -60°C

- Color-coded valve handles and labeled valve plates make SOPs easy to follow

- Removable mesh work bench conveniently hold vessel lids and tools for easy access

- PSI peer-reviewed, 50 state compliant, ASME certified, UL

- On-site training and installation service

DOWNLOAD OUR FREE

5.HX

HYDROCARBON

EXTRACTOR SPEC SHEET

DOWNLOAD OUR FREE

5.HX

HYDROCARBON

EXTRACTOR SPEC SHEET